Basic knowledge about telephone pole transformer

Basic knowledge about telephone pole transformer

A telephone pole transformer is a single-phase transformer. We can first understand what a single-phase transformer is, that is, a transformer whose primary winding and secondary winding are single-phase.

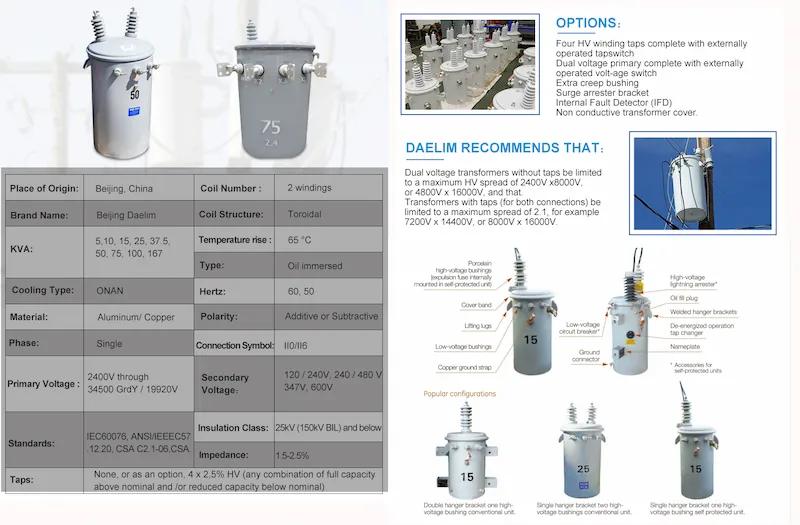

Beijing Daelim is a professional manufacturer and seller of telephone pole transformers, with more than ten years of experience in transformer production and export. Transformers manufactured by Daelim conform to IEEE, CSA, UL, and many other international standards. Daelim's hot-selling products include telephone pole transformers, pad-mounted transformers, power transformers, substation transformers, and distribution transformers. Please feel free to contact me for consultation.

What is a telephone pole transformer?

A telephone pole transformer is a single-phase transformer. We can first understand what a single-phase transformer is, that is, a transformer whose primary winding and secondary winding are single-phase. A device that uses the principle of transformer electromagnetic induction to change AC voltage. Its main components are a primary coil, secondary coil, and iron core. In electrical equipment and wireless circuits, it is often used for voltage raising and lowering, impedance matching, safety isolation, etc.

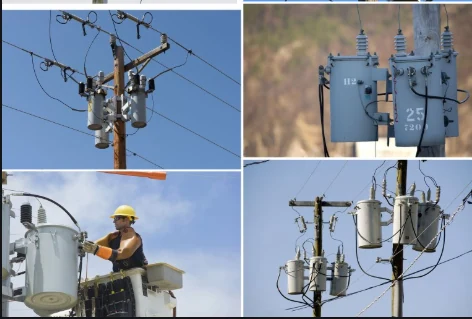

A telephone pole transformer, a single-phase pole-mounted transformer, can also be called a power pole transformer. The telephone pole transformer is cylindrical in appearance, usually installed on cement columns in China and wooden columns in the United States and other regions. The telephone pole transformer serves the distribution network, transforming high-voltage electricity into low-voltage electricity, delivering electricity to vast areas, and meeting the electricity demand of local residents.

Read more about single-phase pole transformer

What does a transformer on a telephone pole do?

Two basic functions of the transformer:

(1) The pressure rise and falls. The living electricity is 220 volts, and the industrial safety lighting is 36 volts. The voltage of the welding machine needs to be adjusted. The voltage is reduced to the required voltage by the principle of electromagnetic mutual inductance of the main and auxiliary coils of the transformer. In the process of long-distance voltage transmission, the voltage is raised to reduce the voltage loss, usually to several thousand volts or even tens of thousands of volts, which is the function of the transformer.

(2) Impedance matching. In the electronic circuit, in order to make the signal unimpeded, the transformer is used for impedance matching, such as old-fashioned broadcasting. Because the constant voltage output is adopted, the horn is a high-impedance horn, and the output transformer is used for matching.

A telephone pole transformer is generally a small transformer, which can transform the high voltage of more than 10 kV into 220 kV for the electricity of several nearby households. It is not necessary to draw a long wire from the terminal transformer, thus achieving the purpose of saving investment.

Learn more: 3 Phase Pad Mounted Transformer

What is inside a transformer on a telephone pole?

A transformer is basically composed of an iron core and winding:

(1) iron core

The iron core forms the magnetic circuit system of the transformer and serves as the mechanical skeleton of the transformer. It is composed of two parts: an iron core column and an iron yoke. The transformer winding is sleeved on the iron core column, and the iron yoke plays the role of connecting the iron core column to close the magnetic circuit. The requirement of the iron core is that magnetic conductivity should be good, hysteresis loss and eddy current loss should be as small as possible, so a 0.35 mm thick silicon steel sheet is adopted. At present, domestic silicon steel sheets include hot-rolled silicon steel sheets, cold-rolled non-oriented silicon steel sheets, and cold-rolled grain-oriented silicon steel sheets. From the 1960s to the 1970s, hot-rolled silicon steel sheets were mainly used in power transformers produced in China. Because of its high iron loss, the magnetic conductivity energy was correspondingly poor, and the core stacking coefficient was low (because both sides of silicon steel sheets were coated with insulating paint), so it is no longer used. At present, domestic low-loss energy-saving transformers all use cold-rolled grain-oriented silicon steel sheet, which has low iron loss and high core stacking coefficient (because the silicon steel sheet is insulated by oxide film on its surface, it is unnecessary to apply insulating paint).

The structure of the transformer core can be divided into two categories: core transformer and shell transformer. The core transformer is a type in which windings are placed on the core columns on both sides to form the winding surrounding the core. Shell transformer is to place the winding on the core column in the middle to form the shape that the core surrounds the winding.

(2) Winding (coil)

The coil of the transformer is usually called winding, which is the circuit part of the transformer. Small transformers are usually wound with insulated enameled round copper wire, while those with larger capacity are wound with flat copper or aluminum wire.

① Concentric winding

For transformers with low voltage, high current, and large capacity, because the low voltage winding leads are very thick, they can also be placed outside. There is a gap between the high and low-voltage windings, which can be used as the oil passage of the oil-immersed transformer, which is beneficial to the heat dissipation of the windings and serves as the insulation between the two windings.

Concentric winding can be divided into cylindrical winding, spiral winding, and continuous winding according to different winding methods. Concentric winding, with its simple structure and easy manufacture, is commonly used in heart-type transformers. It is the most common winding structure, and domestic power transformers basically adopt this structure.

② Overlapping winding

Overlapping winding, also known as cake winding, divides high-voltage winding and low-voltage winding into several wire cakes, which are alternately arranged along the height of core columns. In order to facilitate insulation, low-voltage windings are generally placed on the top and bottom layers. This winding form is mainly used in transformers with low voltage and high current, such as electric furnace transformers with large capacity, resistance welding machines (such as spot welding, rolling welding, and butt welding machines) transformers, etc.

Maybe enjoy: How To Purchase A 1000kva Transformer In 2022? - Daelim Belefic

How many amps is a telephone pole?

Generally, the high-voltage side of the telephone pole transformer is 10KV, and the low-voltage side is 0.4kV Its safe distance is 1.5m. Generally, the wires erected by utility poles over eight meters carry a high voltage of 10-20 kV. The voltages transmitted by the distant lines are above 20 kV. Because the lines have a certain step-down, the higher the voltage, the farther the transmission distance. Generally, the poles of agricultural electricity are below eight meters, and the high voltage of the lines above 10 kV is transformed into the low voltage power electricity of 380 volts by a transformer. It is delivered to the residential quarters by a three-phase four-wire system. In order to ensure the balance of the three-phase current of the transformer, electricians will make reasonable three-phase distribution according to the power consumption. 20 volts is used for lighting, but only one of the three phases is relative to the zero line. For example, the A-plus zero line is used in community A, the B-plus zero line is used in community B, and the C-plus zero line is used in community C. It should be noted here that the zero lines are all public and can be used casually, but the live line is not allowed.

Get it now: Three-phase Transformer Industry Basic Guidelines 2022 | Daelim Belefic

What is inside an electric pole transformer?

When we open the tank cover of the electric pole transformer, we will see components such as iron cores, coils, tap changer, and insulating materials. Among them, iron cores and coils are the core of the transformer, and other components mainly play a role in improving operation and protection.

These components are installed inside the transformer tank and soaked in liquid. The liquid is a high-quality mineral oil that is specially refined or the environment -friendly vegetable oil. These liquids are mainly to prevent dust and humid air from entering the inside of the transformer, improving the insulation performance of the winding, and cooling through the flow.

Try for free: 50 kVA Transformer, Get The Best Price

What does a transformer on an electric pole do?

A transformer on an electric pole usually has two applications

1. Improve or reduce the voltage level in the power grid to meet residents' electricity and industrial electricity;

2. Emergency temporary power supply for construction and disaster relief site

The capacity of the transformer installed on the electric pole is usually not higher than 300kva, otherwise, the electric pole will not bear the weight. The side of the transformer will be designed with 2-4 lifting lugs, which are convenient to install on the electric pole.

You may enjoy: The 150 kVA transformer introduction

How does a telephone pole transformer work?

A telephone pole transformer is an electrical appliance that converts the voltage and transmits electric power. Its primary side is connected to the power supply, and the power supply voltage receives the electric energy in the power network. The secondary side is the output end, which is connected to the electrical equipment and supplies the electrical energy received from the power supply to the electrical load. When the primary winding is powered on, under the rated voltage, there is an alternating current with a power frequency of 50Hz in the primary winding. When the voltage is constant, the magnetic flux in the iron core remains constant, and this magnetic flux is the main magnetic flux. When the secondary circuit of the transformer is open, that is, the transformer is in the no-load state, the current flowing through the primary winding is the no-load current, and the product of the no-load current and the number of turns N of the primary winding of the transformer, that is, in, is the primary magnetic potential side of the transformer.

According to the principle of electromagnetic induction, when the changing magnetic flux passes through the coil, the induced electromotive force can be generated. As the magnetic flux passes through two sets of windings on the same iron core at the same time, an induced potential E is generated in the primary winding of the transformer, and an induced potential E is generated at both ends of the secondary winding. If the primary winding of the transformer is connected to the load, a load current will flow through the load, so that the transformer will transfer the electric power received from the power supply to the load and output electric energy. This is the basic working principle of the transformer.

Read my article on How to test a power transformer?

Telephone pole transformer explosion

A telephone pole transformer is generally an oil-immersed transformer, and the transformer oil tank is filled with transformer oil, which is a combustible liquid with a flash point above 140℃. The winding of the transformer generally adopts Class A insulation, and cotton yarn, cotton cloth, natural silk, paper, and similar organic matters are used as insulation materials for winding; The core of the transformer is supported and padded with wooden blocks and cardboard, all of which are combustible materials. Therefore, the transformer is in great danger of fire and explosion. When a short-circuit discharge occurs inside the transformer, the high-temperature arc may cause the transformer oil to decompose and gasify rapidly, forming a high pressure in the transformer oil tank. When the pressure exceeds the mechanical strength of the fuel tank, an explosion occurs; Or the decomposed oil-gas mixture and transformer oil-gas are ejected from the explosion-proof pipe of the transformer in large quantities, which may cause a fire. The basic causes of fire and explosion in the telephone pole transformer are as follows:

(1)

The insulation of winding insulation is cotton yarn, cotton cloth,

paper, etc., which causes a short circuit of transformer winding due to

aging or damage. If it is heated by overload or corroded by oleic acid

of a transformer, its insulation performance will be aged and

deteriorated, its voltage tolerance will be reduced, and even its

insulation function will be lost; Manufacturing, installation, and

maintenance of transformers may also damage or damage winding

insulation. Due to the aging or damage of the insulation of the

transformer winding, the inter-turn and interlayer short circuit of the

winding may be caused, and the arc generated by the short circuit will

make the winding burn. At the same time, the combustible gas produced by

the arc decomposition of transformer oil is mixed with air to a certain

concentration, which will form an explosive mixture, and it will burn

or explode in case of a spark.

(2) The high temperature or electric spark caused by poor contact of the coil is between the coils wound in the transformer, between the coil end and the tap, and at the terminal where the oil level is exposed. If the connection is not good, an electric spark or arc may be caused by loosening or disconnection; When the position of the tap changer is not correct and the contact is not good, the contact resistance may be too high, resulting in local overheating and high temperature, which may cause oil and gas from transformer oil decomposition to cause combustion and explosion.

(3) Flashover caused by leakage, oil leakage, or long-term accumulation of grease in transformer lead bushing, poor manufacturing, improper operation and maintenance of capacitor bushing, or long-term operation all cause insulation damage and aging in the bushing, resulting in insulation breakdown and high temperature causing bushing explosion and fire.

(4) The aging and deterioration of transformer oil cause the flashover transformer to run at a high temperature all year round. If impurities such as moisture, oxygen, rust, dust, and fibers permeate into the oil, the transformer oil will gradually age and deteriorate, and the insulation performance will be reduced. When the insulation of the transformer winding is also damaged and deteriorated, an internal spark flashover or insulation breakdown will be formed, resulting in an explosion and fire in the transformer.

(5) Insulation damage between silicon steel sheets of transformer core caused by fire and explosion caused by other reasons; Inflammable articles piled up around the transformer appears as external fire sources; The short circuit caused by animals approaching the live parts can cause the transformer to catch fire or explode.

Try to free: Substation Transformer Ultimate Guide, You Need To Know

How much copper is in a power pole transformer?

Winding and silicon steels account for about 70%of the total weight of the power pole transformer. The weight of copper in the power pole transformer is about 30%-40%.

For example, a 25 kVA power pole transformer's total weight is 225kg. Then, the total weight of the copper is about 68kg. The 50 kVA power pole transformer, is 320kg, of which the weight of the copper is about 96kg.

Read more: 25 kVA Transformer, Get The Price Quickly

How much does a power pole transformer weigh?

Power pole transformer usually has cylindrical and square, with various capacities. Material and capacity are the main factors that affect the weight of the transformer. The larger the capacity, the heavier the transformer. The weight of copper transformer is about 20% heavier than aluminum.

For example, the total weight of a 100 kVA power pole transformer produced by Daelim is about 530kg, 167 kVA power pole transformer is about 680kg.

Read my article on The Ultimate Guide To 100 kVA Transformer

How long does it take to replace a power pole transformer?

The time to replace the transformer needs to be disassembled according to the on-site transformer, experimental trials, wiring, etc. In addition, the working load of high, medium, and low-voltage transformers is also different. Small transformers can be completed for several hours. The large ones take a few weeks. The power pole transformer is usually a small transformer. If the preparation work is sufficient, you can complete the replacement installation in a few hours.

What type of transformer is on a utility pole?

The utility pole is a pillar made of composite materials such as wood, metal, concrete, or glass fiber, which is used to support overhead power lines and various other public utilities. Therefore, the load of the utility pole is limited, suitable for installing a small distribution transformer. The capacity of the single-phase utility pole transformer and three-phase oil immersion transformer is not more than 500 kVA.

These transformers are used for two different types of power lines:

1. Perform electrical energy transmission between the substation,

2. Distribute a lower voltage power supply to the terminal customer for direct use.

Keep reading: How Much You Know For The Different Types Of Transformers?

How much does a utility pole transformer cost?

The utility pole transformer's

voltage and capacity will not be large, so the cost will be cheaper.

Depending on the voltage, capacity, and type, the price is about $

1500-8000. To get specific prices and technical parameters, please

contact the DAELIM team.

How much voltage is in a transformer on a pole?

From the above content, we know that the voltage and capacity will not be very large. DB Transformer can design and produce various types of pole transformer

The standard voltage includes: 12470Y/7200V, 13200Y/7620V, 13800Y/7957V, 34500Y/19920V, 7.2KV, 12.47kv, 13.2kv, 14.4KV, 24.94kv, 34.5kv.

If you need another voltage level of the pole transformer, please send the specific requirements to service@daelim-electric.com or pingruidan@daelim-electric.com, we will give the quotation within 24 hours.

In conclusion

Beijing Daelim is a professional manufacturer and seller of telephone pole transformers, with more than ten years of experience in transformer production and export. Transformers manufactured by Daelim conform to IEEE, CSA, UL, and many other international standards. Telephone pole transformers manufactured by Dalin are sold to Canada, Honduras, Peru, and many other countries, and their good quality and short delivery time are widely praised by customers. Please feel free to contact me for consultation.

No comments:

Post a Comment