Desalination is the premier international journal dedicated to communicating the latest developments in ...

Desalination

From Wikipedia, the free encyclopedia

Desalination is a process that removes

minerals from saline

water. More generally, desalination refers to the removal of salts and minerals from a target substance,

[1] as in

soil desalination, which is an issue for agriculture.

[2]

Saltwater is desalinated to produce water suitable for

human consumption or

irrigation. One

by-product of desalination is

salt. Desalination is used on many seagoing

ships and

submarines. Most of the modern interest in desalination is focused on cost-effective provision of

fresh water for human use. Along with recycled

wastewater, it is one of the few rainfall-independent water sources.

[3]

Due to its energy consumption, desalinating sea water is generally more costly than fresh water from rivers or

groundwater,

water recycling and

water conservation.

However, these alternatives are not always available and depletion of

reserves is a critical problem worldwide. Currently, approximately 1% of

the world's population is dependent on desalinated water to meet daily

needs, but the UN expects that 14% of the world's population will

encounter water scarcity by 2025.

[4]

Desalination is particularly relevant in dry countries such as

Australia, which traditionally have relied on collecting rainfall behind dams for water.

According to the International Desalination Association, in June

2015, 18,426 desalination plants operated worldwide, producing 86.8

million cubic meters per day, providing water for 300 million people.

[5] This number increased from 78.4 million cubic meters in 2013,

[4] a 57% increase in just 5 years. The single largest desalination project is

Ras Al-Khair in

Saudi Arabia, which produced 1,025,000 cubic meters per day in 2014,

[4] although this plant is expected to be surpassed by a plant in California.

[6] Israel produces a higher proportion of its water than any other country, totaling 40% of its water use.

[7]

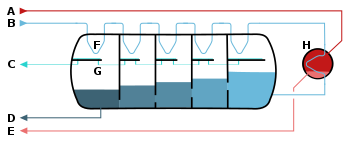

Schematic of a

multistage flash desalinator

A – steam in

B – seawater in

C – potable water out

D – waste out

E – steam out

F – heat exchange

G – condensation collection

H – brine heater

Methods

The traditional process used in these operations is

vacuum distillation—essentially

boiling it to leave impurities behind. In desalination, atmospheric

pressure is reduced, thus lowering the required temperature. Liquids

boil when the

vapor pressure

equals the ambient pressure and vapor pressure increases with

temperature. Thus, because of the reduced temperature, low-temperature

"waste" heat from electrical power generation or industrial processes

can be employed.

[citation needed]

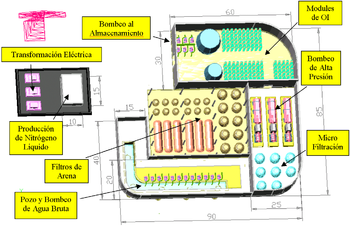

Reverse osmosis desalination plant in Barcelona, Spain

The principal competing processes use membranes to desalinate, principally applying

reverse osmosis.

[8] Membrane processes use semipermeable membranes and pressure to separate salts from water.

Reverse osmosis plant

membrane systems typically use less energy than thermal distillation.

Desalination remains energy intensive, however, and future costs will

continue to depend on the energy prices.

[9]

Considerations and criticism

Energy consumption

Energy consumption of seawater desalination has reached as low as 3 kWh/m

3,

[10]

including pre-filtering and ancillaries, similar to the energy

consumption of other fresh water supplies transported over large

distances,

[11] but much higher than local fresh water supplies that use 0.2 kWh/m

3 or less.

[12]

A minimum energy consumption for seawater desalination of around 1 kWh/m

3 has been determined,

[13][14] excluding prefiltering and intake/outfall pumping. Under 2 kWh/m

3[15] has been achieved with

reverse osmosis membrane technology, leaving limited scope for further energy reductions.

Supplying all US domestic water by desalination would increase

energy consumption by around 10%, about the amount of energy used by domestic refrigerators.

[16] Domestic consumption is a relatively small fraction of the total water usage.

[17]

Note: "Electrical equivalent" refers to the amount of electrical

energy that could be generated using a given quantity of thermal energy

and appropriate turbine generator. These calculations do not include the

energy required to construct or refurbish items consumed in the

process.

Cogeneration

Cogeneration

is generating excess heat and electricity generation from a single

process. Cogeneration can provide usable heat for desalination in an

integrated, or "dual-purpose", facility where a power plant provides the

energy for desalination. Alternatively, the facility's energy

production may be dedicated to the production of potable water (a

stand-alone facility), or excess energy may be produced and incorporated

into the energy grid. Cogeneration takes various forms, and

theoretically any form of energy production could be used. However, the

majority of current and planned cogeneration desalination plants use

either

fossil fuels or

nuclear power as their source of energy. Most plants are located in the

Middle East or

North Africa,

which use their petroleum resources to offset limited water resources.

The advantage of dual-purpose facilities is they can be more efficient

in energy consumption, thus making desalination more viable.

[19][20]

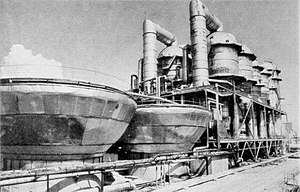

The Shevchenko BN350, a nuclear-heated desalination unit

The current trend in dual-purpose facilities is hybrid

configurations, in which the permeate from reverse osmosis desalination

is mixed with distillate from thermal desalination. Basically, two or

more desalination processes are combined along with power production.

Such facilities have been implemented in Saudi Arabia at

Jeddah and

Yanbu.

[21]

A typical

Supercarrier in the US military uses nuclear power to desalinate 400,000 US gallons (1,500,000 l; 330,000 imp gal) of water per day.

[22]

Economics

Costs of desalinating sea water (infrastructure, energy, and maintenance) are generally higher than fresh water from rivers or

groundwater,

water recycling, and

water conservation,

but alternatives are not always available. Desalination costs in 2013

ranged from US$0.45 to $1.00/cubic metre ($US2 to 4/kgal). (1 cubic

meter is about 264 gallons.) More than half of the cost comes directly

from energy cost, and since energy prices are very volatile, actual

costs can vary substantially.

[23]

The cost of untreated fresh water in the developing world can reach US$5/cubic metre.

[24]

Average water consumption and cost of supply by sea water desalination at US$1 per cubic metre(±50%)

| Area |

Consumption USgal/person/day |

Consumption litre/person/day |

Desalinated Water Cost US$/person/day |

| USA |

100 |

378 |

0.38 |

| Europe |

50 |

189 |

0.19 |

| Africa |

15 |

57 |

0.06 |

| UN recommended minimum |

13 |

49 |

0.05 |

Factors that determine the costs for desalination include capacity

and type of facility, location, feed water, labor, energy, financing and

concentrate disposal. Desalination

stills control pressure, temperature and brine concentrations to optimize efficiency.

Nuclear-powered desalination might be economical on a large scale.

[25][26]

While noting costs are falling, and generally positive about the

technology for affluent areas in proximity to oceans, a 2004 study

argued, "Desalinated water may be a solution for some water-stress

regions, but not for places that are poor, deep in the interior of a

continent, or at high elevation. Unfortunately, that includes some of

the places with biggest water problems.", and, "Indeed, one needs to

lift the water by 2,000 m (6,600 ft), or transport it over more than

1,600 km (990 mi) to get transport costs equal to the desalination

costs. Thus, it may be more economical to transport fresh water from

somewhere else than to desalinate it. In places far from the sea, like

New Delhi, or in high places, like

Mexico City,

transport costs could match desalination costs. Desalinated water is

also expensive in places that are both somewhat far from the sea and

somewhat high, such as

Riyadh and

Harare. By contrast in other locations transport costs are much less, such as

Beijing,

Bangkok,

Zaragoza,

Phoenix, and, of course, coastal cities like

Tripoli."

[27] After desalination at

Jubail, Saudi Arabia, water is pumped 200 mi (320 km) inland to

Riyadh.

[28] For coastal cities, desalination is increasingly viewed as a competitive choice.

In 2014, the Israeli facilities of Hadera, Palmahim, Ashkelon, and

Sorek were desalinizing water for less than US$0.40 per cubic meter.

[29] As of 2006, Singapore was desalinating water for US$0.49 per cubic meter.

[30] The city of

Perth began operating a reverse osmosis seawater desalination plant in 2006.

[31] A desalination plant now operates in

Sydney,

[32] and the

Wonthaggi desalination plant was under construction in

Wonthaggi, Victoria.

The Perth desalination plant is powered partially by renewable energy from the

Emu Downs Wind Farm.

[33][34] A wind farm at

Bungendore in

New South Wales was purpose-built to generate enough

renewable energy to offset the Sydney plant's energy use,

[35] mitigating concerns about harmful

greenhouse gas emissions.

In December 2007, the South Australian government announced it would

build a seawater desalination plant for the city of Adelaide, Australia,

located at

Port Stanvac. The desalination plant was to be funded by raising water rates to achieve full cost recovery.

[36][37]

A January 17, 2008, article in the

Wall Street Journal stated, "In November, Connecticut-based Poseidon Resources Corp. won a key regulatory approval to build the $300 million water-

desalination plant in

Carlsbad, north of

San Diego.

The facility would produce 50,000,000 US gallons (190,000,000 l;

42,000,000 imp gal) of drinking water per day, enough to supply about

100,000 homes.

[38] As of June 2012, the cost for the desalinated water had risen to $2,329 per acre-foot.

[39] Each $1,000 per acre-foot works out to $3.06 for 1,000 gallons, or $.81 per cubic meter.

[40]

Poseidon Resources made an unsuccessful attempt to construct a

desalination plant in Tampa Bay, FL, in 2001. The board of directors of

Tampa Bay Water

was forced to buy the plant from Poseidon in 2001 to prevent a third

failure of the project. Tampa Bay Water faced five years of engineering

problems and operation at 20% capacity to protect marine life. The

facility reached capacity only in 2007.

[41]

In 2008, a

Energy Recovery Inc. was desalinating water for $0.46 per cubic meter.

[42]

Environmental

Intake

In the

United States, cooling water intake structures are regulated by the

Environmental Protection Agency

(EPA). These structures can have the same impacts to the environment as

desalination facility intakes. According to EPA, water intake

structures cause adverse environmental impact by sucking fish and

shellfish or their eggs into an industrial system. There, the organisms

may be killed or injured by heat, physical stress, or chemicals. Larger

organisms may be killed or injured when they become trapped against

screens at the front of an intake structure.

[43] Alternative intake types that mitigagte these impacts include beach wells, but they require more energy and higher costs.

[44]

The

Kwinana Desalination Plant opened in Perth in 2007. Water there and at Queensland's

Gold Coast Desalination Plant and Sydney's

Kurnell Desalination Plant is withdrawn at 0.1 m/s (0.33 ft/s), which is slow enough to let fish escape. The plant provides nearly 140,000 m

3 (4,900,000 cu ft) of clean water per day.

[33]

Outflow

Desalination processes produce large quantities of

brine,

possibly at above ambient temperature, and contain residues of

pretreatment and cleaning chemicals, their reaction byproducts and heavy

metals due to corrosion.

[45]

Chemical pretreatment and cleaning are a necessity in most desalination

plants, which typically includes prevention of biofouling, scaling,

foaming and corrosion in thermal plants, and of biofouling, suspended

solids and scale deposits in membrane plants.

[46]

To limit the environmental impact of returning the brine to the

ocean, it can be diluted with another stream of water entering the

ocean, such as the outfall of a

wastewater treatment

or power plant. With medium to large power plant and desalination

plants, the power plant's cooling water flow is likely to be several

times larger than that of the desalination plant, reducing the salinity

of the combination. Another method to reduce the dilute the brine is to

mix it via a diffuser in a mixing zone. For example, once a pipeline

containing the brine reaches the sea floor, it can split into many

branches, each releasing brine gradually through small holes along its

length. Mixing can be combined with power plant or wastewater plant

dilution.

Brine is denser than seawater and therefore sinks to the ocean bottom

and can damage the ecosystem. Careful reintroduction can minimize this

problem. Typical ocean conditions allow for rapid dilution, thereby

minimizing harm.

Alternatives without pollution

Some methods of desalination, particularly in combination with

evaporation ponds,

solar stills, and

condensation trap (

solar desalination),

do not discharge brine. They do not use chemicals or burn fossil fuels.

They do not work with membranes or other critical parts, such as

components that include heavy metals, thus do not produce toxic waste

(and high maintenance).

A new approach that works like a solar still, but on the scale of industrial evaporation ponds is the

integrated biotectural system.

[47]

It can be considered "full desalination" because it converts the entire

amount of saltwater intake into distilled water. One of the advantages

of this system is the feasibility for inland operation. Standard

advantages also include no air pollution and no temperature increase of

endangered natural water bodies from power plant cooling-water

discharge. Another important advantage is the production of sea salt for

industrial and other uses. As of 2015, 50% of the world's sea salt

production relies on fossil energy sources.

[48]

Alternatives to desalination

Increased

water conservation

and efficiency remain the most cost-effective approaches in areas with a

large potential to improve the efficiency of water use practices.

[49] Wastewater reclamation provides multiple benefits over desalination.

[50] Urban runoff and storm water capture also provide benefits in treating, restoring and recharging groundwater.

[51]

A proposed alternative to desalination in the American Southwest is

the commercial importation of bulk water from water-rich areas either by

oil tankers

converted to water carriers, or pipelines. The idea is politically

unpopular in Canada, where governments imposed trade barriers to bulk

water exports as a result of a

North American Free Trade Agreement (NAFTA) claim.

[52]

Public health concerns

Desalination

removes iodine from water and could increase the risk of iodine

deficiency disorders. Israeli researchers claimed a possible link

between seawater desalination and iodine deficiency,

[53] finding deficits among

euthyroid adults exposed to iodine-poor water

[54] concurrently with an increasing proportion of their area's drinking water from seawater reverse osmosis (SWRO).

[55] They later found probable iodine deficiency disorders in a population reliant on desalinated seawater.

[56]

Experimental techniques

Other desalination techniques include:

Waste heat

Diesel generators

commonly provide electricity in remote areas. About 40%–50% of the

energy output is low-grade heat that leaves the engine via the exhaust.

Connecting a

membrane distillation system to the diesel engine exhaust repurposes this low-grade heat for desalination. The system actively cools the

diesel generator,

improving its efficiency and increasing its electricity output. This

results in an energy-neutral desalination solution. An example plant was

commissioned by Dutch company

Aquaver in March 2014 for

Gulhi,

Maldives.

[57][58]

Low-temperature thermal

Originally stemming from

ocean thermal energy conversion research,

low-temperature thermal desalination (LTTD) takes advantage of water boiling at low pressure, even at

ambient temperature.

The system uses pumps to create a low-pressure, low-temperature

environment in which water boils at a temperature gradient of 8–10 °C

(46–50 °F) between two volumes of water. Cool ocean water is supplied

from depths of up to 600 m (2,000 ft). This water is pumped through

coils to condense the water vapor. The resulting condensate is purified

water. LTTD may take advantage of the temperature gradient available at

power plants, where large quantities of warm wastewater are discharged

from the plant, reducing the energy input needed to create a temperature

gradient.

[59]

Experiments were conducted in the US and Japan to test the approach.

In Japan, a spray-flash evaporation system was tested by Saga University.

[60]

In Hawaii, the National Energy Laboratory tested an open-cycle OTEC

plant with fresh water and power production using a temperature

difference of 20 C° between surface water and water at a depth of around

500 m (1,600 ft). LTTD was studied by India's National Institute of

Ocean Technology (NIOT) in 2004. Their first LTTD plant opened in 2005

at Kavaratti in the

Lakshadweep

islands. The plant's capacity is 100,000 L (22,000 imp gal;

26,000 US gal)/day, at a capital cost of INR 50 million (€922,000). The

plant uses deep water at a temperature of 10 to 12 °C (50 to 54 °F).

[61] In 2007, NIOT opened an experimental, floating LTTD plant off the coast of

Chennai,

with a capacity of 1,000,000 L (220,000 imp gal; 260,000 US gal)/day. A

smaller plant was established in 2009 at the North Chennai Thermal

Power Station to prove the LTTD application where power plant cooling

water is available.

[59][62][63]

Thermoionic process

In October 2009, Saltworks Technologies announced a process that uses solar or other thermal heat to drive an

ionic current that removes all

sodium and

chlorine ions from the water using ion-exchange membranes.

[64]

Evaporation and condensation for crops

The

Seawater greenhouse uses natural evaporation and condensation processes inside a

greenhouse powered by solar energy to grow crops in arid coastal land.

Other approaches

Forward osmosis

One process was commercialized by Modern Water PLC using

forward osmosis, with a number of plants reported to be in operation.

[65][66][67]

Small-scale solar

The United States, France and the United Arab Emirates are working to develop practical

solar desalination.

[68]

AquaDania's WaterStillar has been installed at Dahab, Egypt, and in

Playa del Carmen, Mexico. In this approach, a solar thermal collector

measuring two square metres can distill from 40 to 60 litres per day

from any local water source – five times more than conventional stills.

It eliminates the need for plastic

PET bottles or energy-consuming water transport.

[69]

In Central California, a startup company WaterFX is developing a

solar-powered method of desalination that can enable the use of local

water, including runoff water that can be treated and used again. Salty

groundwater in the region would be treated to become freshwater, and in

areas near the ocean, seawater could be treated.

[70]

Passarell

The

Passarell process uses reduced atmospheric pressure rather than heat to

drive evaporative desalination. The pure water vapor generated by

distillation is then compressed and condensed using an advanced

compressor. The compression process improves distillation efficiency by

creating the reduced pressure in the evaporation chamber. The compressor

centrifuges

the pure water vapor after it is drawn through a demister (removing

residual impurities) causing it to compress against tubes in the

collection chamber. The compression of the vapor increases its

temperature. The heat is transferred to the input water falling in the

tubes, vaporizing the water in the tubes. Water vapor condenses on the

outside of the tubes as product water. By combining several physical

processes, Passarell enables most of the system's energy to be recycled

through its evaporation, demisting, vapor compression, condensation, and

water movement processes.

[71]

Geothermal

Geothermal energy can drive desalination. In most locations,

geothermal desalination beats using scarce groundwater or surface water, environmentally and economically.

[citation needed]

Nanotechnology

Nanotube membranes

may prove to be effective for water filtration and desalination

processes that would require substantially less energy than reverse

osmosis.

[72]

Hermetic, sulphonated nano-composite membranes have shown to be

capable of reducing almost all forms of contamination to the parts per

billion level. These nano-materials, using a non-reverse osmosis

process, have little or no susceptibility to high salt concentration

levels.

[73][74][75]

Abstracted animation of the nanoscale graphene membrane desalination process.

Biomimesis

Biomimetic membranes are another approach.

[76]

Electrochemical

In

2008, Siemens Water Technologies announced technology that applied

electric fields to desalinate one cubic meter of water while using only a

purported 1.5 kWh of energy. If accurate, this process would consume

one-half the energy of other processes.

[77] As of 2012 a demonstration plant was operating in Singapore.

[78]

Researchers at the University of Texas at Austin and the University of

Marburg are developing more efficient methods of electrochemically

mediated seawater desalination.

[79]

Freeze-thaw

Freeze-thaw desalination uses freezing to remove fresh water from frozen seawater.

[80]

Electrokinetic shocks

Membraneless desalination at ambient temperature and pressure used electrokinetic shocks waves.

[81]

Anions and cations in salt water are exchanged for carbonate anions and

calcium cations respectively using electrokinetic shockwaves. Calcium

and carbonate ions react to form

calcium carbonate, which precipitates, leaving fresh water. Theoretical energy efficiency of this method is on par with

electrodialysis and

reverse osmosis.

Facilities

Estimates vary widely between 15,000–20,000 desalination plants producing more than 20,000 m

3/day. Micro desalination plants operate near almost every

natural gas or

fracking facility is found in the United States.

[citation needed]

In nature

Mangrove leaf with salt crystals

Evaporation of water over the oceans in the

water cycle is a natural desalination process.

The formation of

sea ice produces ice with little salt, much lower than in seawater.

Seabirds distill seawater using

countercurrent exchange in a

gland with a

rete mirabile. The gland

secretes highly concentrated brine

stored near the nostrils above the beak. The bird then "sneezes" the

brine out. As freshwater is not usually available in their environments,

some seabirds, such as

pelicans,

petrels,

albatrosses,

gulls and

terns, possess this gland, which allows them to drink the salty water from their environments while they are far from land.

[82][83]

Mangrove

trees grow in seawater; they secrete salt by trapping it in parts of

the root, which are then eaten by animals (usually crabs). Additional

salt is removed by storing it in leaves that fall off. Some types of

mangroves have glands on their leaves, which work in a similar way to

the seabird desalination gland. Salt is extracted to the leaf exterior

as small

crystals, which then fall off the leaf.

Willow trees and

reeds absorb salt and other contaminants, effectively desalinating the water. This is used in artificial

constructed wetlands, for treating

sewage.

[citation needed]

See also

References

No comments:

Post a Comment