- DESCRIPTION

- BRAND

- ADDITIONAL INFORMATION

- TECH SPEC

- SOFTWARE

- FREQUENTLY ASKED QUESTIONS ABOUT EVO

- REVIEWS (0)

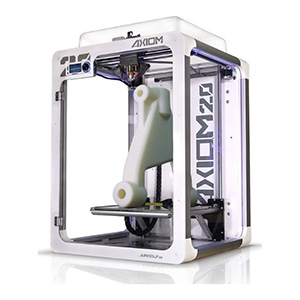

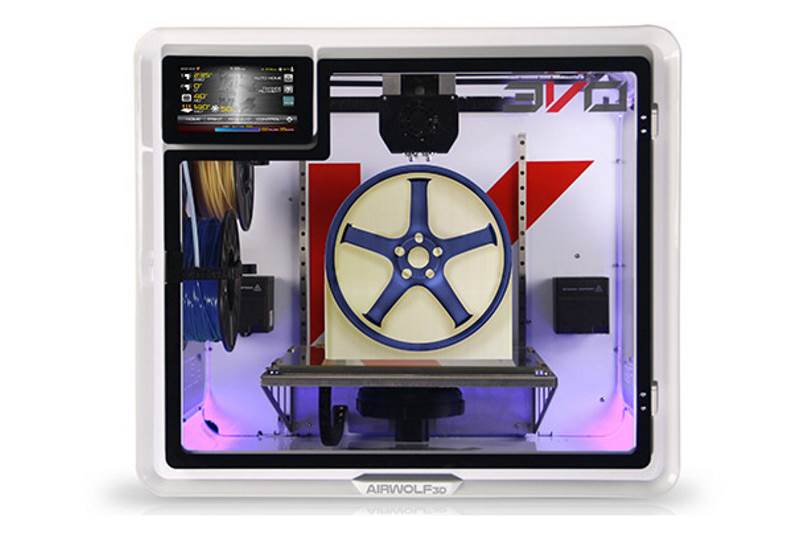

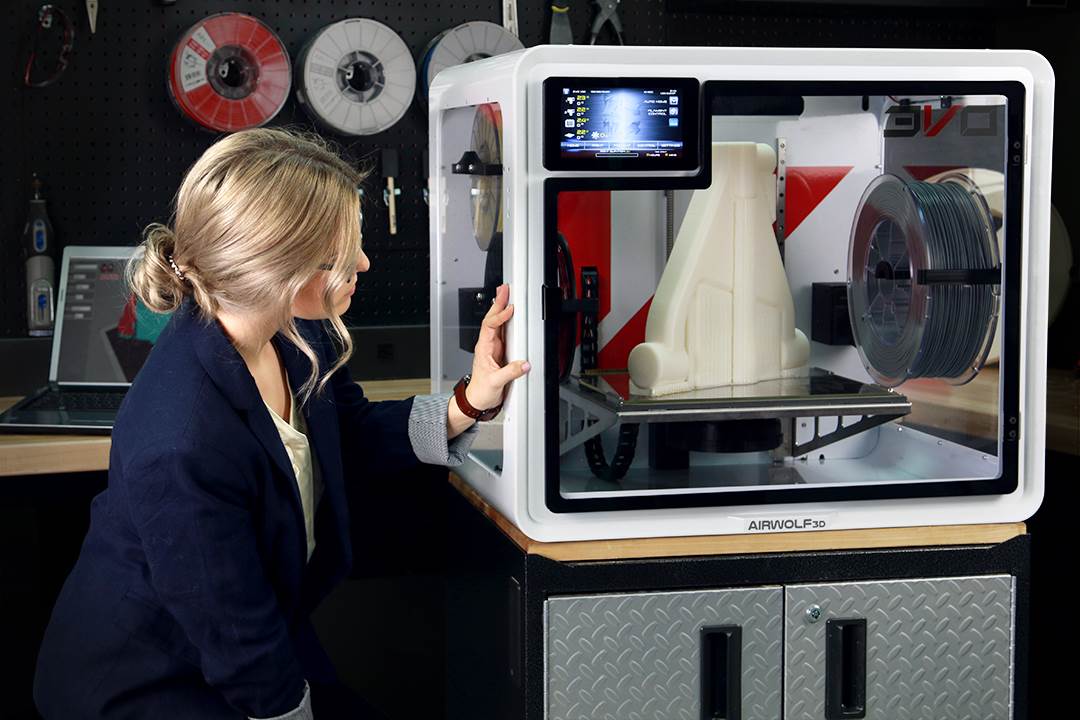

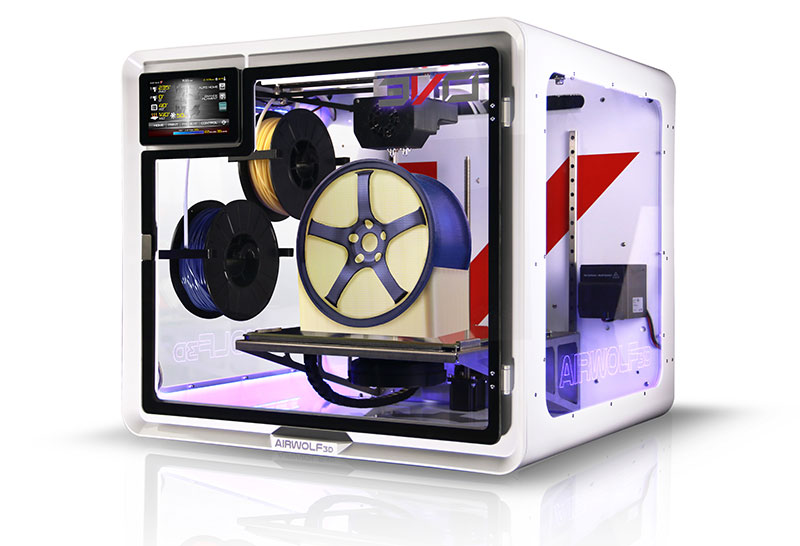

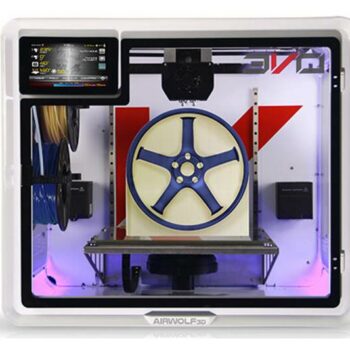

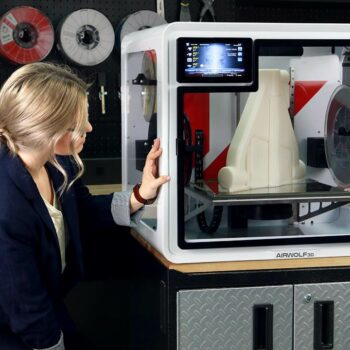

Easily manufacture large functional prototypes and production parts at top speeds with Airwolf 3D EVO, the world’s most advanced desktop Additive Manufacturing Center (3D Printer).

EVO AT A GLANCE

OVERSIZED BUILD ENVIRONMENT

Manufacture large size, end-use parts within the EVO’s huge build volume in over 40 different materials. Optimized for production, the 12 x 12 x 11-inch enclosed build volume is configured for producing large, strong parts.

![]()

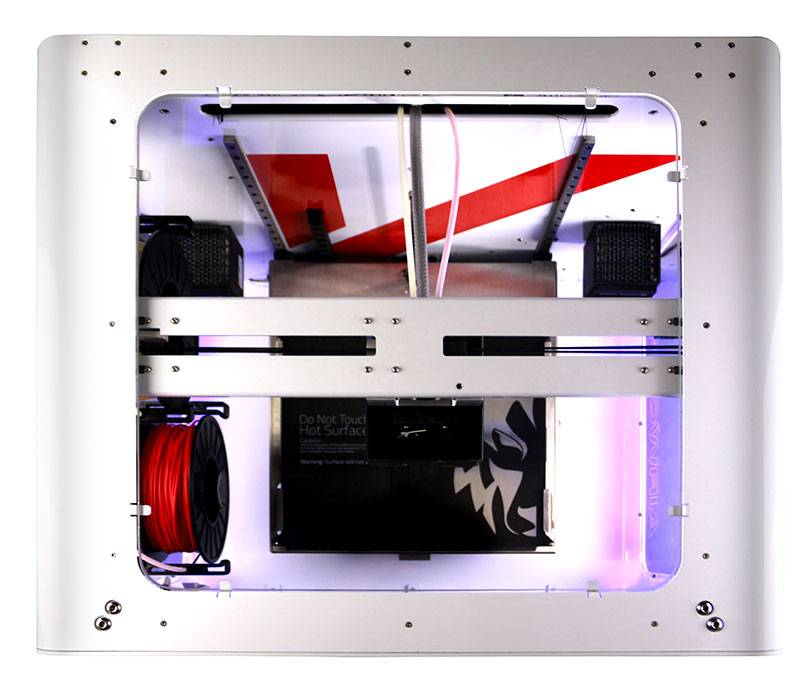

TRI-HEAT™ TECHNOLOGY

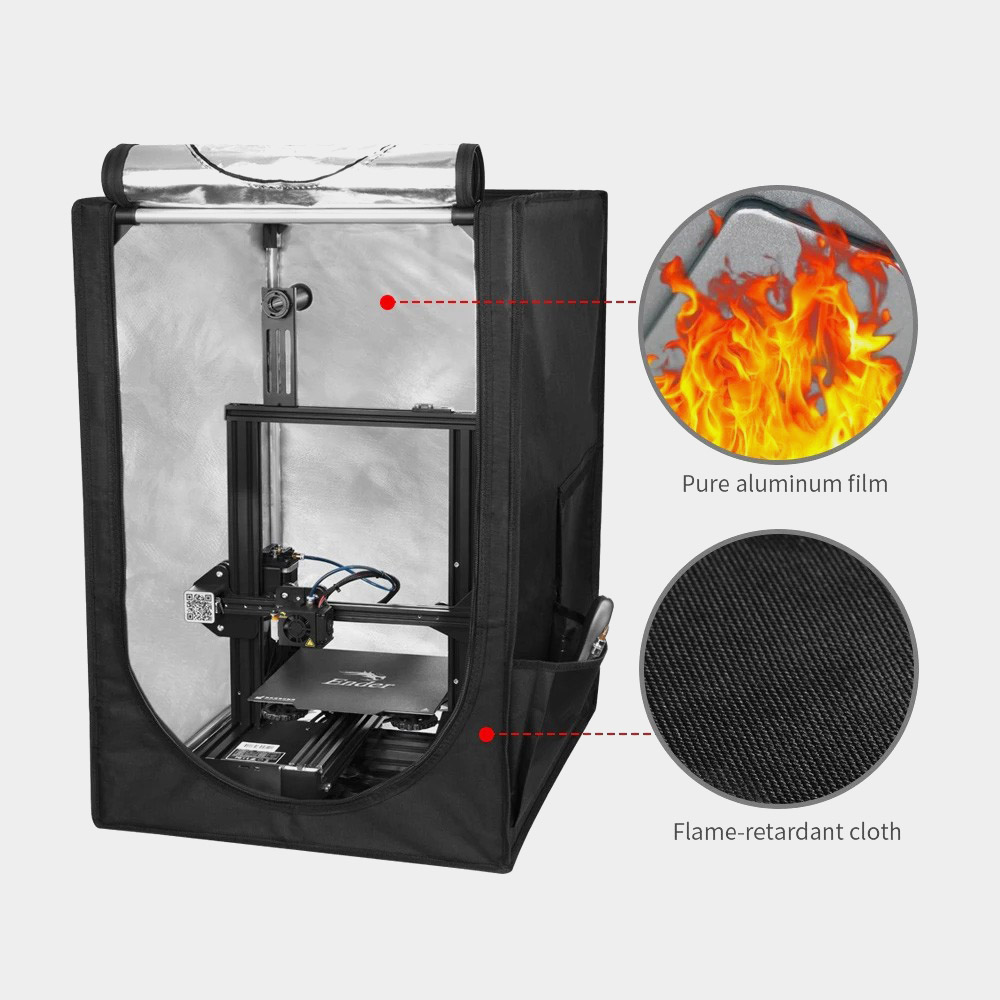

Manufacture the highest quality parts possible on an industrial 3D printer, thanks to proprietary Tri-Heat™ technology that warms the chamber and dries the filament within.

AUTO-LEVELING & CALIBRATION

Enjoy Airwolf 3D’s proprietary auto-leveling technology along with AutoPrime, and Sweep. Ultra-durable Extended-Life nozzles save time and money while providing higher precision, speed and efficiency on 3D printing.

AIR CLEANSING SYSTEM

EVO features an oversized air purifying system for active containment of UFP and VOC emissions, providing an extra layer of protection and peace of mind when 3D printing in schools or smaller spaces.

PARTSAVE™

Avoid part failure due to power outage, an accidentally unplugged machine, or other unexpected interruptions. As soon as power of the 3D printer is restored, PartSave™ empowers you to resume production right where it left off.

FAILSAFE™

Whether you run out of filament or experience a jam, FailSafe™ has you covered. Just place the print head where you left off, and FailSafe™ will do the rest, restoring your print and completing the 3D print with time to spare.

WHAT COMES WITH YOUR Airwolf 3D EVO ADDITIVE MANUFACTURING CENTER (3D PRINTER)?

- (1) Extra 0.50 Extended-Life Nozzle

- (1) Double-Sided Flex-Resistant Glass

- (1) 2oz Bottle of Wolfbite Premium Adhesive Solution

- (1) 2-Pound Spool of ABS Filament (2.85mm)

- (1) USB Drive

- (1) Nozzle-Cleaning Tool

- (1) APEX Software

- One-Year Parts and Labor Warranty

- 2 Service Maintenances included in first year

PARTSAVE™

For the first time in history, you can start, stop, and resume the 3D manufacturing process at any time, thanks to EVO’s industry-first PartSave™ technology. Gone are the days of losing prints due to machine failure, power failure, or accidental shutdown.Whether you need to pause part production for one minute or one hundred years, PartSave™ ensures the 3D printing process will be ready to continue as soon as you are.

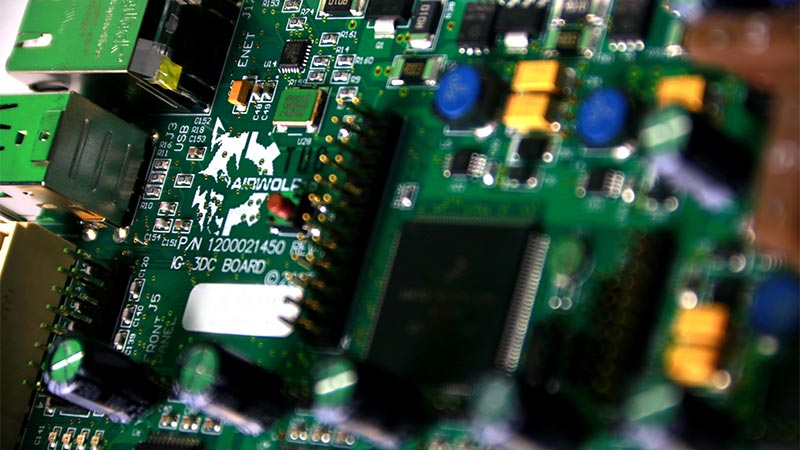

GENESIS MICROCONTROLLER

Both the brain and heart of the Airwolf 3D EVO 3D Printer, Airwolf 3D’s proprietary GENESIS Microcontroller drives the leaps and bounds that EVO has made in desktop additive manufacturing technology.

Fully proprietary and engineered from the ground up to support high-performance industrial manufacturing, the GENESIS board is an automotive-grade 32-bit redundant embedded controller that delivers 2-3 times higher speeds, more precision, and greater control at ultra-high temperatures than any other desktop 3D manufacturing system on the market.

MATRIX TOUCHSCREEN CONTROL

Control Airwolf 3D EVO with a single touch. A spacious 7″ full-color touch display makes it easy to control everything from PartSave™, material selection, internal ambient temperature, and expert settings to an on-screen keyboard for writing and executing g-Code on the fly.

TRI-HEAT™ TECHNOLOGY ENSURES PART INTEGRITY AND KEEPS FILAMENT DRY

Manufacture the highest quality parts possible on a desktop additive manufacturing system, thanks to the EVO’s proprietary Tri-Heat™ technology. Two internal heaters and a high-temperature bed maintain precise temperature control and heated airflow for optimum manufacturing of stronger, smoother, higher-quality engineering-grade parts from materials including ABS, nylon, and polycarbonate.

The Integrated Filament Drying System further facilitates optimal printing conditions, drying up to 10 pounds of material at a time for immediate extrusion or long-term storage.

MAINTENANCE-FREE PRECISION

The CoreXY Motion System receives a leading-edge update thanks to CNC-style linear precision guides. Up until now, the successful integration of a heavy-duty linear-guide-based motion control system was available only in high-end 3D printing systems at over five times the price of the Airwolf 3D EVO 3D printer. One of the most future-proof design elements of the EVO AMC, the linear-guide-based CoreXY Motion System provides unparalleled manufacturing precision with zero maintenance.

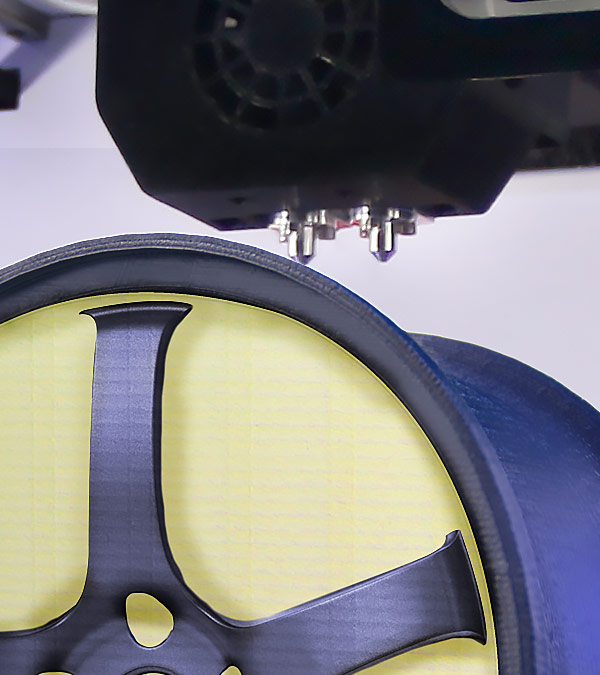

DUAL HIGH-FLOW AX2 EXTRUSION HEADS

Manufacture large parts quickly with the Airwolf 3D EVO’s industry-leading 0.4lb/hour maximum material deposition rate. A cartridge-style planetary extruder assembly achieves increased torque capacity for faster extrusion speeds while an unbreakable three-bolt-reinforced hot end precisely distributes over 40 materials ranging from PLA and ABS to exotic materials including carbon-fiber-reinforced nylon and PC as well as HydroFill, Airwolf 3D’s proprietary water-soluble support.Performance is further optimized by extended-life replaceable nozzles that help minimize part distortion.

BALL SCREW Z STAGE

The EVO’s bulletproof z stage comprises a proprietary coupling linking a ball screw with a stepper motor and is powerful enough to support up to 50 pounds and provides precision of nearly one thousandth of an inch over its 11-inch build height, providing incredible accuracy.Approximately the size of a human hair, the precision movement is barely discernible by the human eye.

ULTRA-RUGGED, USER-CENTRIC CONSTRUCTION

The strongest 3D printer on the market, the Airwolf 3D EVO has a 100% aluminum unitized frame constructed in a rigid monocoque to maximize structural integrity while minimizing bulk and weight. The unitized build platform supports up to 50 pounds and also employs one-piece construction to save weight and space in order to maximize strength while minimizing part distortion.With an oversized 1000-watt power supply, the EVO has power in reserves, easily adapting to ultra-demanding applications in even the harshest environments. An automatic circuit breaker provides a safer, more reliable, and more serviceable system than conventional fuse replacement.Though rugged and unbreakable, the Airwolf 3D EVO is light enough to transport easily and can be stacked up to four units high for multiplied part production.

OVER 40 MATERIALS, INCLUDING METAL

Manufacture in over 40 materials ranging from PLA and ABS to exotic materials like metal, carbon fiber-reinforced nylon, polycarbonate, and HydroFill Water-Soluble Support. Produce larger, more complex parts than ever before, thanks to the carefully controlled thermal environment offered by Airwolf 3D EVO’s Tri-Heat™ Enclosed Build Chamber and Integrated Filament Drying System.

AIRWOLF 3D EVO OFFICIAL PRODUCT PAGE

https://airwolf3d.com/shop/industrial-3d-printer/

Contact our sales for more details.